- Willcox And Gibbs Sewing Machine Serial Number Lookup

- Willcox And Gibbs Serial Numbers

- Willcox And Gibbs Sewing Machine Serial Numbers

- Willcox And Gibbs Sewing Machine Serial Numbers

James Gibbs had originally seen a woodcut picture of a Grover & Baker machine in 1855. The picture only showed the top half of the machine, so Gibbs tried to imagine how a stitch was formed. He could tell the needle went in and out of the same hole in the fabric, rather than travelling completely through as in hand sewing, and came up with the idea that sewing had to have been accomplished with a chainstitch.

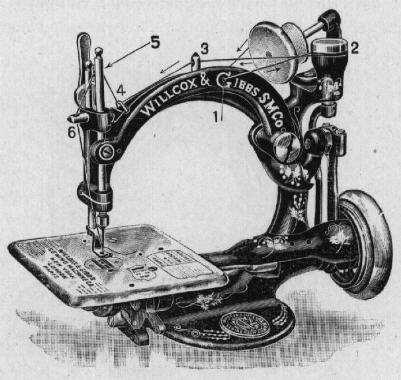

Rewire Willcox and Gibbs Motor - Part 1 This tutorial is a step by step photo documentation of rewiring the motor on a vintage (1937) Willcox and Gibbs chain stitch sewing machine motor. List of Materials. Model represented: Willcox and Gibbs improved lockstitch roller puller. Descriptive Notes: Line drawing of Willcox and Gibbs lockstitch roller puller and description of its use; list of Willcox and Gibbs Sewing Machine Company branches. Smithsonian Location: NMAH. Textiles Collection.

- Willcox and Gibbs Decals. Hidden below the needleplate is the serial number. I submitted a photo of this machine to the Needlebar website a while ago, and was.

- Willcox & gibbs serial numbers, sewalot www.sewalot.com - A site dedicated to sewing, sewing machines, collectors of sewing machines and other related topics. Saved by Gracie Day.

In January 1856 while visiting his father he saw a Singer machine in a tailor's shop for the first time. To him it looked too heavy and expensive and he decided to pursue his idea of a simpler, lightweight chainstitch machine. His work on it had to fit around his employment and he was hampered by a lack of tools and materials, but by April of that year his first model was ready and his employers agreed to finance the patenting of it.

Having been to Washington's patent office he went to Philadelphia to show his model to James Willcox, who was specializing in building models of new inventions. Willcox was impressed with Gibbs' machine and put him to work with his own son, Charles Willcox. James Gibbs took out two patents (December 16, 1856 and January 20, 1857), before the all important patent above, from June 2, 1857.

In this patent the revolving hook takes the loop of thread and holds it while the feed moves the fabric until the needle descends once more through the loop. The thread is twisted in its rotation before a new loop is started. The machine used a straight needle.

Willcox & Gibbs Automatic Instruction Manual

Gibbs' 1856 Patent Model

Courtesy of Claire Sherwell from the archives in the Smithsonian Institute.

This is Gibbs' 1856 patent model:

Willcox And Gibbs Sewing Machine Serial Number Lookup

Gibbs' 1857 Patent Model

Courtesy Claire Sherwell, from the Smithsonian Institution

This is the actual model submitted by James E A Gibbs to the patent office in 1857 and now held by the Smithsonian Institute, still with its patent tag present.

Although it doesn't at first look familiar, it is the most important Gibbs patent. It covers the formation of his famous and enduring chainstitch looper. It was re-issued the following year.

It covers the formation of his famous and enduring chainstitch looper. It was re-issued the following year. It uses a straight needle:

The hook

'The hook is so arranged in relation to the needle-arm that when the latter shall have reached its lowest point of stroke the hook is just facing the loop which the needle has brought through the cloth. The next motion of the needle will be ascending.

The loop is thereby loosened and opens. In the same time the hook will advance and penetrate the loop, as shown in Fig. 4. The loop is now gradually spread by the hook during the next following part of its revolution. The hook is gradually swelling, (in thickness,) and is concavely shaped where the loop is in contact therewith, for the purpose of not drawing more thread than is strictly necessary.

After the loop has thus been drawn open, it will slip off the hook and lodge into the angular recess r, which the hook is forming with the shaft. This is done during the time the hook is revolving from position Fig. 5 to position Fig. 6.

The loop is then twisted—i. e., the thread which has been behind the needle is brought to the front, while the thread in front of the needle is turned toward the rear of the loop. This is effected by the spur or cast-off x. This cast-off is so arranged in relation to the hook and angular recess r that the loop, is spread for the hook-nose to pass through on taking a fresh loop from the needle.

At this moment the hook has two loops engaged, the fresh loop at the nose and the preceding loop, which now bears against the convex part of the hook. (See Fig. 4.) The next motion of the hook will allow this latter loop to slip off entirely from the hook, as shown in Fig. 5, and is drawn tight by drawing open the new loop.

This series of operations is repeated at every revolution of the hook.'

Gibbs' 1858 Patent Model

Serial #10365, pictures taken in the Smithsonian Institute by Claire Sherwell

The machine bears the previous patent of January 20, 1857:

From the Harry Berzack Museum, courtesy of Claire Sherwell.

This J E A Gibbs machine has several differences from the Smithsonian's patent model:

Glass Tension Treadle Model

Courtesy of Mike & Kelly Anderson

Serial #168341

Rose decals: 'extra ornamented'.

Willcox And Gibbs Serial Numbers

Glass tension discs

Rose decals

Comparison of Willcox & Gibbs Handcrank Gantries

Courtesy of Rijnko Fekkes

Gantries on machines dated 1871, 1873 and 1889

Willcox And Gibbs Sewing Machine Serial Numbers

Glass Tension English Hand Model

with Ornamented Gantry

Courtesy of Rijnko Fekkes

Serial #174071

Stitch Formation

Courtesy of Daveofsuffolk.

The illustration shows the formation of the chain stitch.

How the looper works

Spool pin

Courtesy of Claire Sherwell

The Willcox & Gibbs wrench measures approximately 1 5/8' long (shown against a Willcox & Gibbs chainstitch needle) and is used for pushing up the needle into the needle bar and fastening the needle. The needle itself has a long groove all the way up.

Willcox And Gibbs Sewing Machine Serial Numbers

Automatic Chainstitch Machine

Serial #A296632

Courtesy of Fay

Automatic refers to the automatic tension (earlier machines had glass tension discs).

The machine has J.E.A. Gibbs patents June 2-57, July 14-70, April 16-61; Willcox and Carleton June 27-71, July 14-71; and Chas. H Willcox May 31-62, Mch 22-64 and Oct 8-61. It also has Under Royal Letter Patent, James Willcox, July 4-71.

Included was a ruffler with instructions which states the price was $2; a tuckmarker for which the instructions say that an additional Guide Plate was available for tucks less than 1/8 inch wide for fifty cents.

Serial number under hook

Tuck marker

Ruffler

Serial #A684651

Courtesy of MeezerMom

Straw Hat Sewing Machine

Serial #B502942

Courtesy of Jess

The Willcox and Gibbs Sewing Machine Co. (New York) was formed in 1857 by James Willcox and his son Charles, of Philadelphia and James E.A. Gibbs of Pocahontas County, West Virginia. Gibbs patented his first practical single thread rotary twisted chain stitch machine for domestic use in 1856. Willcox was a forward thinking businessman and was in charge of production. He hired the services of the Providence, Rhode Island company of Joseph R. Brown and Lucian Sharpe, who undertook the manufacturing of the machines.

Work began early in 1858 with the local New England Butt Company casting the frames. J.R. Brown and Sharpe were beset with problems and it was 8 months before the first 50 Willcox and Gibbs machines, of the original 100 commissioned orders were finished. Luckily the machine was in instant success and soon the orders were rolling in.

Willcox & Gibbs Silent Automatic

A few years after starting the company Willcox & Gibbs opened its London Offices at 135 Regent Street. Prices for the machines ranged from £8 to £15. All the machine heads were built and shipped over from the United States, but some handwheels and wheel mountings were cast at the Coalbrookdale Company in Shropshire. The Coalbrookdale works near Telford, was in Victorian times, famous for producing high quality ornate iron castings and the wheel mountings made here carry a registration mark for 1869. A special Willcox and Gibbs hand crank mechanism was produced for the European market, but the overall shape of the machine remained the same for the whole of its production life.

Early models used a thread tensioner with glass discs, and some of these have the Willcox and Gibbs badge on the back of the casting and a deeper wooden base than later models.

Willcox & Gibbs Glass Tension

In 1875 the glass tension discs were replaced by an automatic tension device which ensured that the tension did not get out of alignment and which adapted itself to different thicknesses of fabric. These were marketed as the ‘Silent Automatic’ sewing machine. Listed on the cloth plate of all Willcox and Gibbs machines are the patent dates along with a very clever mechanism to show the number of stitches to the inch.

Around 1871 the company’s chief European offices were opened at 150 Cheapside, London. After 1885 the offices were moved to 94 & 96 Wigmore Street and then a few years later to 37 & 39 Moorgate Street. After 1907 the head offices were based at 20 Fore Street London, E.C. and the Willcox and Gibbs Sewing Machine Co.Ltd was founded with branch offices at Nottingham, Manchester, Leeds, Leicester, Luton, Glasgow, Belfast, Paris, Milan, Brussels and an agency at Dresden! They advertised ‘repairing departments’ at all offices and a ‘certified agent’ in most towns.

Machines for the domestic market were sold as either hand or treadle versions but with the arrival of electricity, the machines could have an electric motor attached to the right hand side of the machine in place of the hand wheel.

Willcox & Gibbs Electric

In addition to the domestic market, the company also produced a wide range of industrial models. Between 1878 and 1884 industrial machines were introduced under the names ‘Straw’, ‘Bag’ and ‘Handstitch’ machines and in 1889 a 2 thread ‘overlock’ machine which was able to produce 3000 stitches a minute. In 1889 the first Willcox and Gibbs lockstitch machines appeared on the market. In 1912 a ‘Flatlock’ machine designed for seaming knitted underwear was invented, followed by a ‘Feldlock’ machine designed for seaming tubular garments.

Brown and Sharpe continued to produce the Willcox and Gibbs chain stitch machine in its original shape until 1948. Towards the end of the production the serial numbers changed from the ‘A’ prefix number to ‘B’ prefix numbers and the machines had scalloped bases.

The Willcox & Gibb company finally closed down in 1973.